Cartesian Robots vs. Collaborative Robots: The Best Solution for Precision Dosing and Dispensing

In the era of Industry 4.0 and smart automation, choosing the right robot for precision dosing and fluid dispensing is essential to improve efficiency and reduce waste. The two most common solutions are Cartesian robots and collaborative robots (cobots) each with distinct advantages.

At Alutec Srl, we specialize in Cartesian robotic systems designed for high-performance dosing and dispensing. In this article, we compare these technologies to help you choose the best solution for your automation needs.

What Is a Cartesian Robot? Linear Accuracy for Industrial Automation

Also known as X-Y-Z robots or gantry robots, Cartesian robots move along three linear axes: X, Y, and Z. This mechanical simplicity ensures high rigidity, accuracy, and repeatability — all critical for applications like automated fluid dispensing and precision dosing.

Key Advantages of Cartesian Robots:

- Exceptional precision and repeatability

Linear motion minimizes cumulative error, enabling consistent dosing accuracy. - Robust structural design

Supports heavier loads and resists external forces. - Scalable work areas

Easily customizable for larger applications by extending axis lengths. - User-friendly programming

Straightforward control over linear paths. - High cost-efficiency

Ideal for applications that require high performance at a reasonable cost.

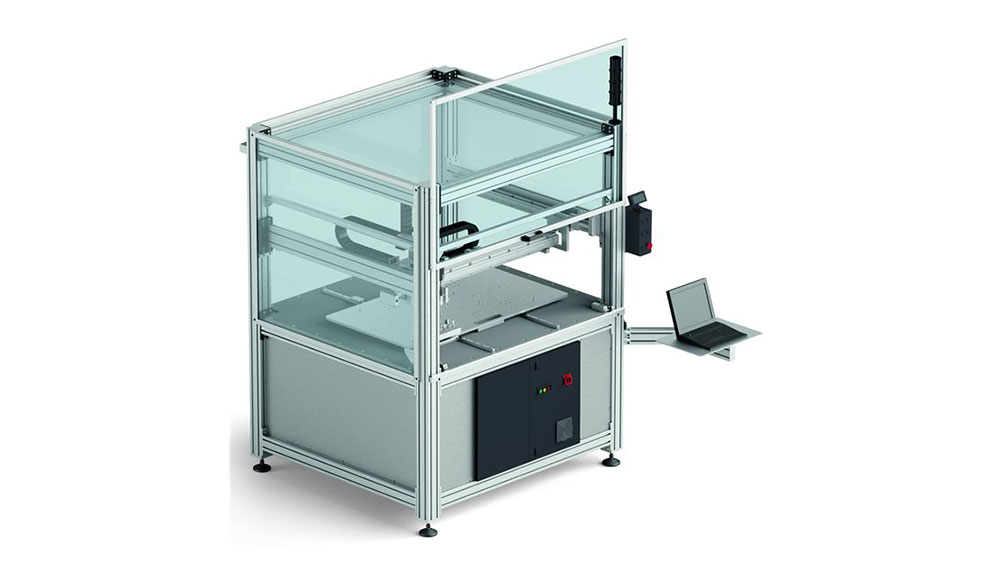

Alutec Cartesian Robots for Precision Dispensing

At Alutec, our Cartesian dosing robot lineup includes the WRa500, WRA300, WRS300, WRL300 and Gantry Robot. These systems feature 3- or 4-axis interpolation and work areas ranging from 300x300mm to over 500x500mm.

Designed for:

- Flexible integration

- Consistent high precision

- Industrial-scale repeatability

These robots are built with ball screw axes and high-rigidity linear guides, mounted on a durable aluminum frame.

Our systems are powered by a proprietary motion control platform and our intuitive ALPHA software, delivering top-tier performance and advanced features.

Connectivity & Integration:

- CANopen and RS232 interfaces

- 16 standard I/O ports

- Fully standalone or integrable with external automation systems

For demanding tasks like adhesive dispensing, sealant application, oil dosing, or other fluid process automation, Alutec Cartesian robots provide unmatched control and efficiency.

What Are Collaborative Robots (Cobots)? Flexibility Meets Human Interaction

Collaborative robots, or cobots, are designed to safely operate alongside human workers. They feature built-in safety systems that reduce speed and force upon contact, eliminating the need for safety barriers.

Benefits of Cobots:

- Fast deployment and high flexibility

Ideal for small batch production or frequently changing setups. - Safe human interaction

Intelligent sensors minimize collision risks. - Compact footprint

Perfect for tight production environments.

Cobots excel in light assembly, visual inspections, pick & place, and operator assistance. Their strength lies in collaboration and adaptability.

Why Alutec Chooses Cartesian Robots for Dosing and Dispensing

While cobots offer flexibility, for high-precision industrial dosing, Cartesian robots deliver superior results.

At Alutec Srl, we believe in the mechanical simplicity, precision, and reliability of Cartesian systems. That’s why we’ve specialized in them for over a decade.

Our Cartesian Robots Offer:

- Maximum dispensing accuracy – Reduce waste and improve final product quality

- Long-term reliability – Fewer maintenance interventions thanks to simple mechanics

- Higher load capacity – Ideal for complex dosing heads

- Lower operating costs – High precision means fewer errors and less rework

- CE-certified safety – Optional optical and mechanical safety features

All our models, including the WRA series, comply with strict European safety standards.

Choosing the Right Robot for Your Automation Needs

The decision between Cartesian and collaborative robots depends entirely on your application.

If your goals include:

- Extreme precision

- High repeatability

- Heavy-duty dispensing operations

then Cartesian robots are the most technologically efficient and cost-effective solution.

FAQ: Cartesian vs. Collaborative Robots

1. What is the main difference between Cartesian robots and cobots?

Cartesian robots follow fixed linear paths for high-precision automation. Cobots are designed for flexible, safe collaboration with humans.

Cartesian robots follow fixed linear paths for high-precision automation. Cobots are designed for flexible, safe collaboration with humans.

2. Are Cartesian robots better for dosing applications?

Yes. Their linear motion ensures high repeatability, making them ideal for fluid dosing and adhesive dispensing.

Yes. Their linear motion ensures high repeatability, making them ideal for fluid dosing and adhesive dispensing.

3. Can Alutec robots be integrated into existing production lines?

Absolutely. Our systems feature standard industrial interfaces (CANopen, RS232) and customizable I/O ports for seamless integration.

Absolutely. Our systems feature standard industrial interfaces (CANopen, RS232) and customizable I/O ports for seamless integration.

4. What industries benefit from Cartesian dosing robots?

Automotive, electronics, medical devices, and packaging anywhere precision and repeatability are essential.

Automotive, electronics, medical devices, and packaging anywhere precision and repeatability are essential.

Contact Alutec for Your Robotic Dosing Solution

At Alutec Srl, we don’t just sell robots we engineer custom automation solutions tailored to your exact needs. Contact us today for a free consultation and discover how our Cartesian robots can optimize your dosing and dispensing processes.

Test us, request technical advice now.

One of our specialists will contact you as soon as possible.