In today’s highly competitive manufacturing environment, industrial material handling requires fast, reliable and easily integrable solutions. Production efficiency, line continuity and operating costs depend directly on the technologies used to move products throughout the production process.

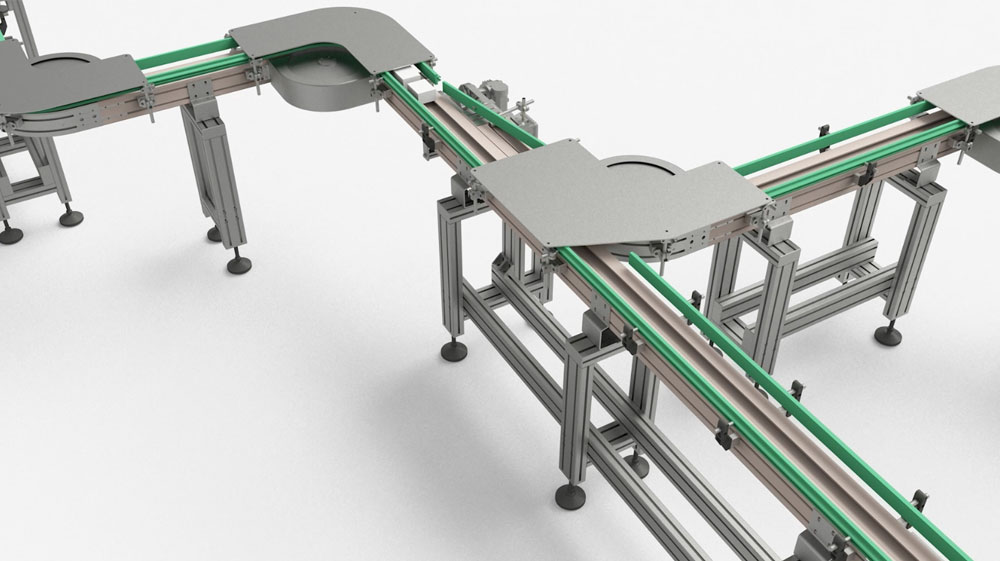

To meet these needs, Alutec developed A-FlexMove, a modular conveyor system designed to deliver maximum flexibility in industrial material handling, from packaging operations to end-of-line automation.

Download

Why flexibility matters in industrial conveying systems

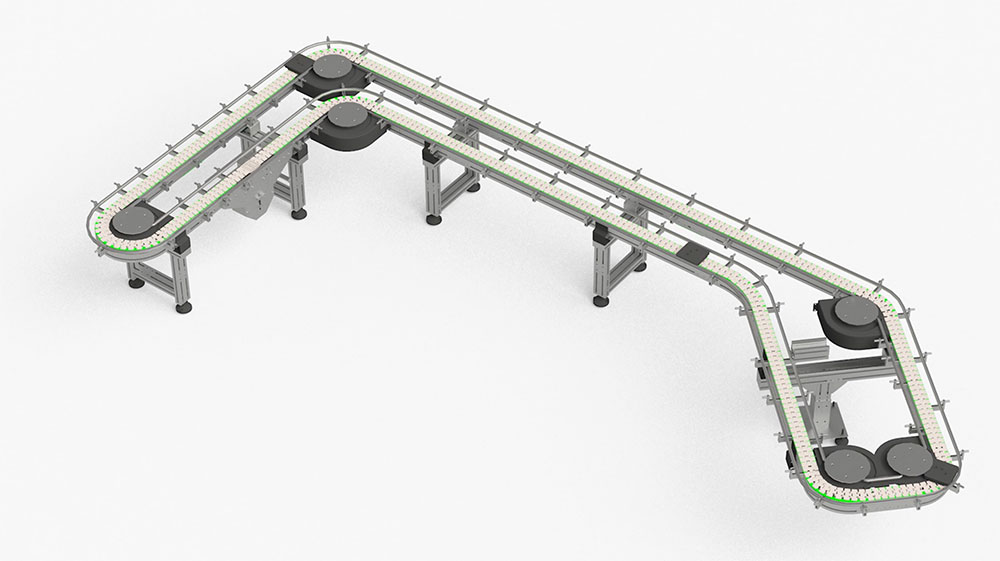

Modern production lines must adapt quickly to changing layouts, formats and speeds. A-FlexMove is not just a conveyor, but a flexible material handling platform that allows products to be diverted, rotated, accumulated and accelerated according to the specific requirements of each line.

Thanks to its compact and intelligent design, A-FlexMove integrates easily into existing conveyor systems, minimizing downtime, reducing maintenance costs and simplifying daily operations. The result is a smoother material flow and consistently high productivity.

How A-FlexMove works

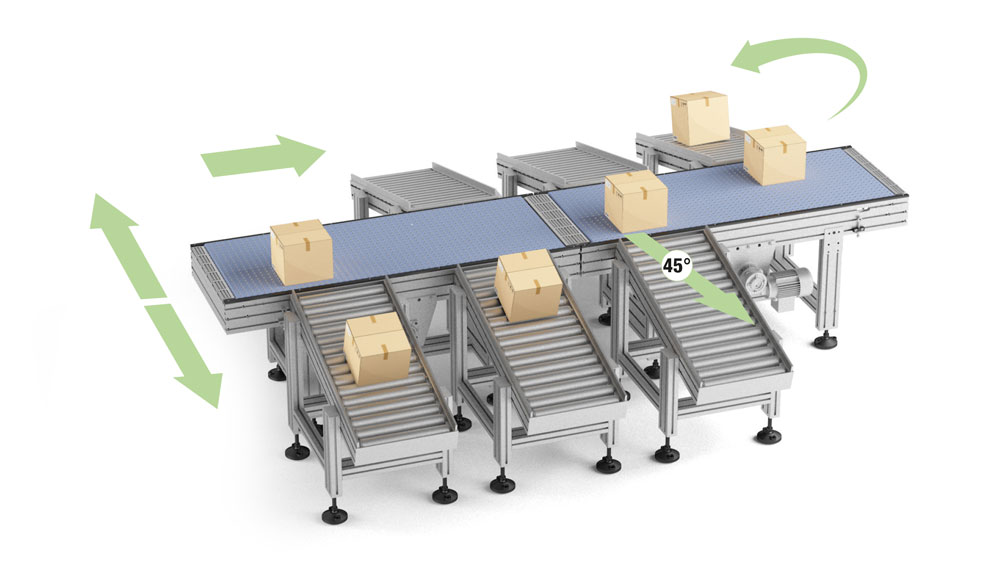

A-FlexMove uses a combination of belts and internal plates to precisely control product movement, enabling advanced industrial material handling applications, including:

- Diverting and sorting systems: straight, 45° or curved product routing

- 360-degree product rotation: ideal for high-speed lines or processes requiring precise orientation

- Accumulation and acceleration conveyors: intelligent flow management for barcode reading, vision inspection, palletizing and timing-sensitive operations

This level of control makes A-FlexMove a highly versatile solution for automated production environments.

Applications of A-FlexMove in industrial material handling

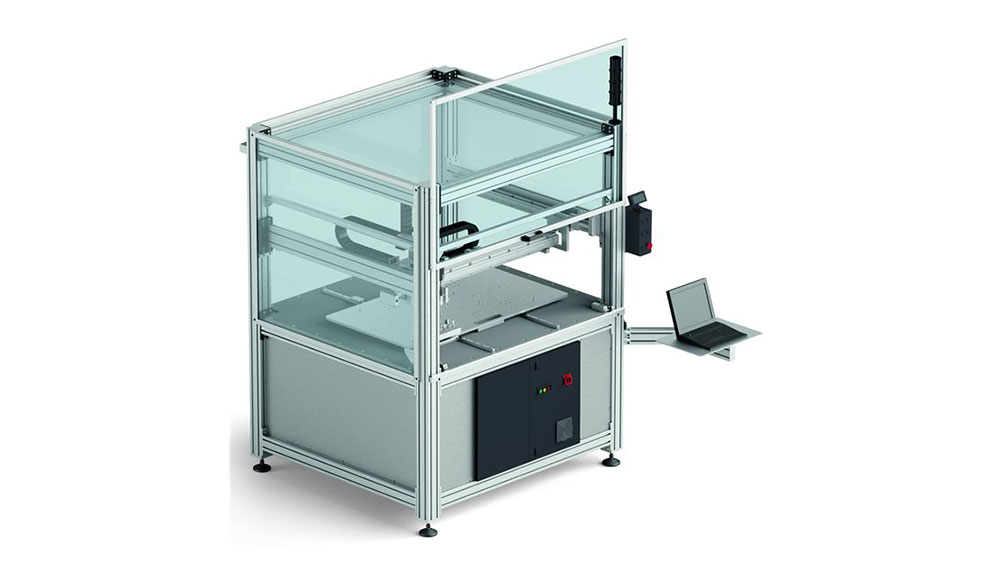

The versatility of A-FlexMove makes it suitable for a wide range of industrial conveying and automation applications, such as:

- logistics centers handling high volumes of light and compact packages

- packaging and labeling machines

- sorting and rejection lines

- inspection and measurement processes

- distribution and automated sorting systems

Wherever products need to be moved quickly, accurately and safely, A-FlexMove delivers reliable performance.

Key benefits of the A-FlexMove modular conveyor system

By choosing A-FlexMove, companies adopt a flexible industrial material handling system that:

- increases production line flexibility

- reduces downtime and maintenance costs

- adapts quickly to new layouts and configurations

- improves processing speed and product quality

Optimize your industrial material handling with A-FlexMove

With A-FlexMove, Alutec provides a modular conveyor technology that combines innovation, flexibility and ease of integration. It is a complete solution for optimizing industrial material handling and improving overall production efficiency.

Want to discover how A-FlexMove can enhance your production line?

Contact us for more information or request a dedicated consultation.

Contact us for more information or request a dedicated consultation.

Test us, request technical advice now.

One of our specialists will contact you as soon as possible.